Key specifications

Material

Max Snow Loads

Max Wind Loads

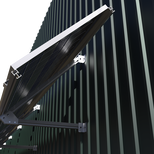

Tilt Angle

PV Panel Orientation

Module

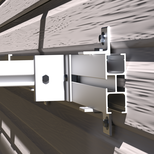

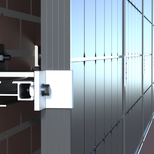

Wall Type

Grounding

Typical Bifacial Gains Observed

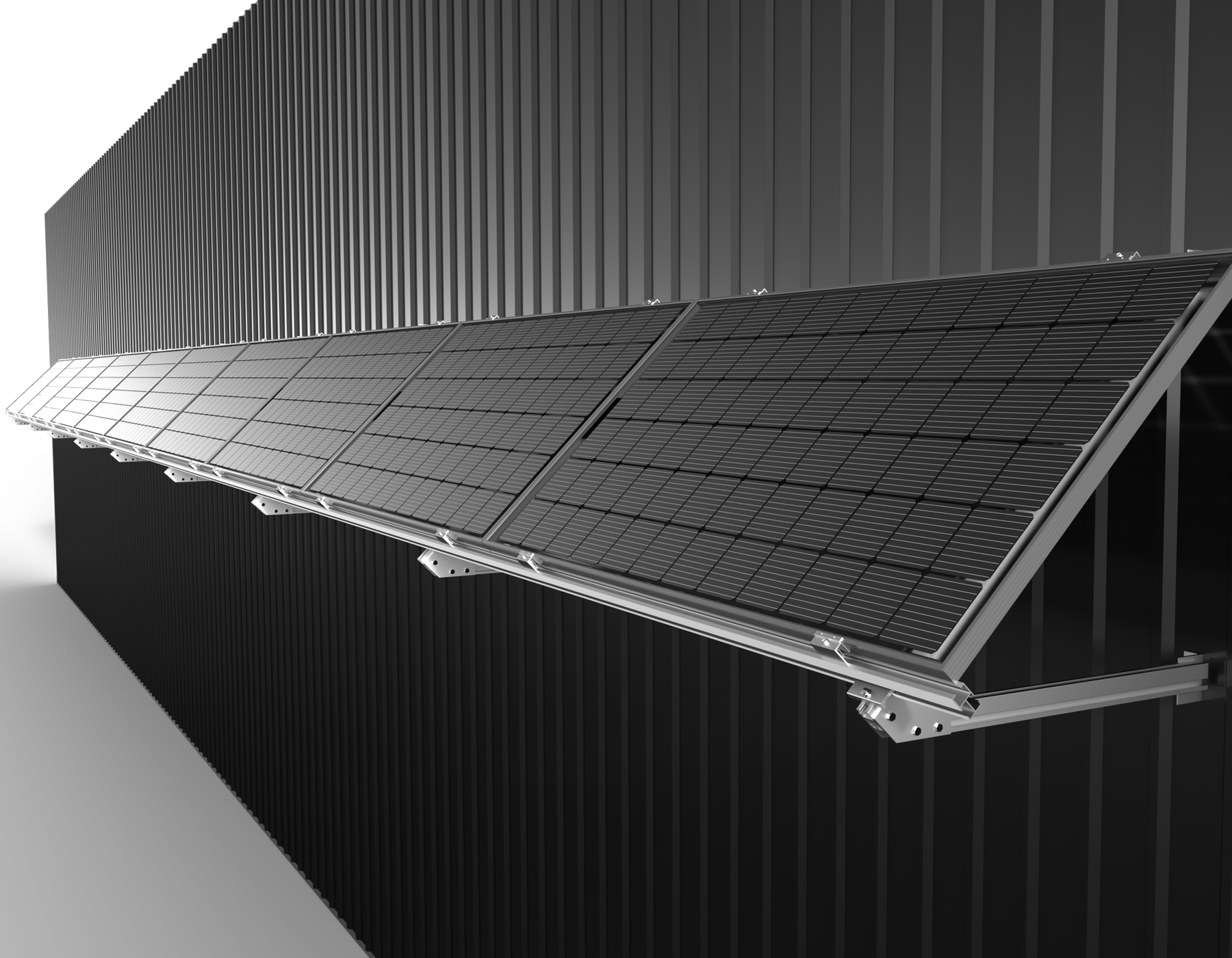

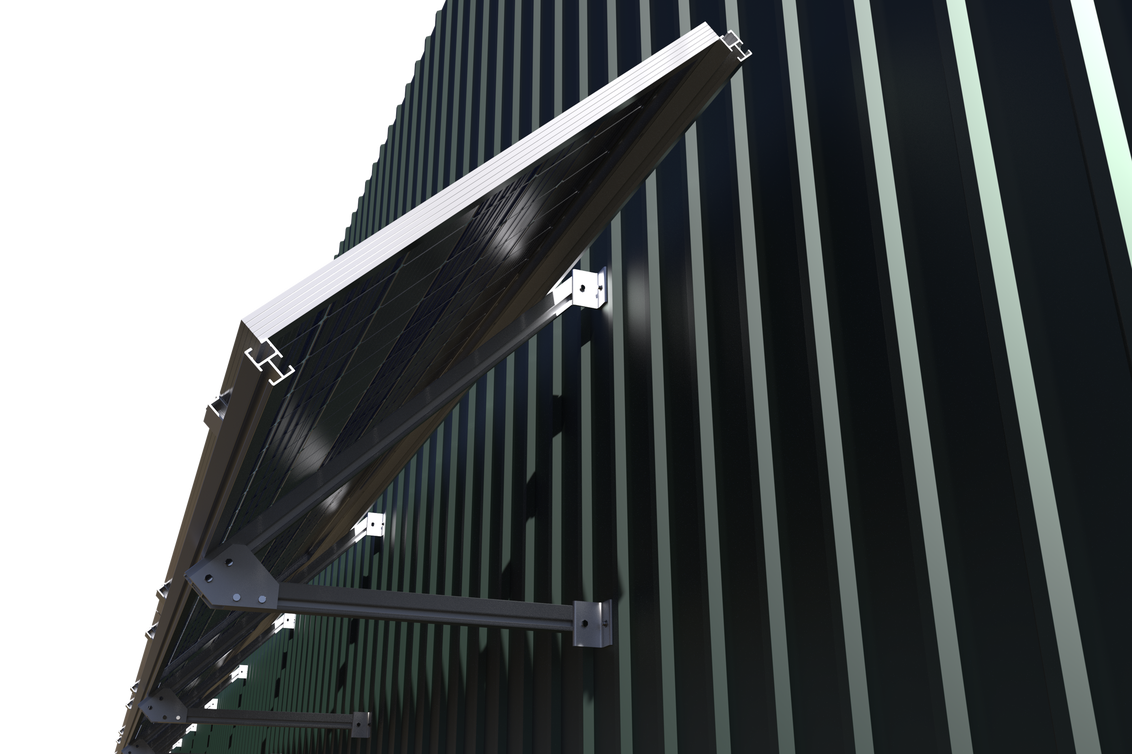

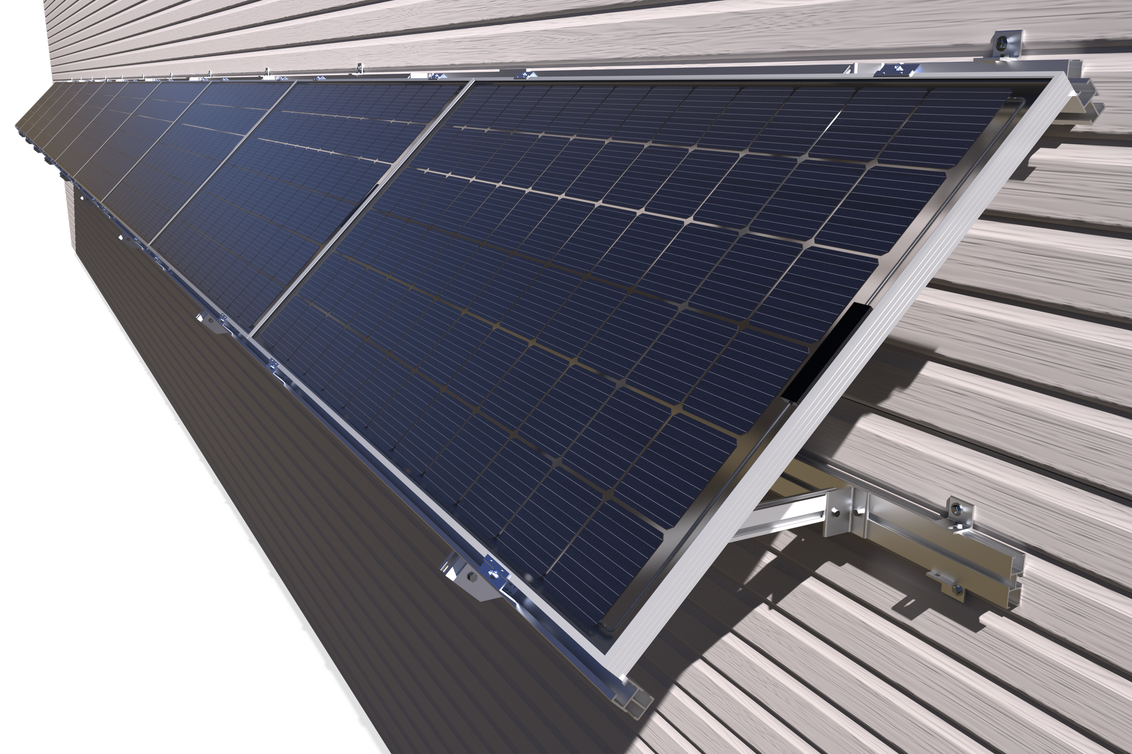

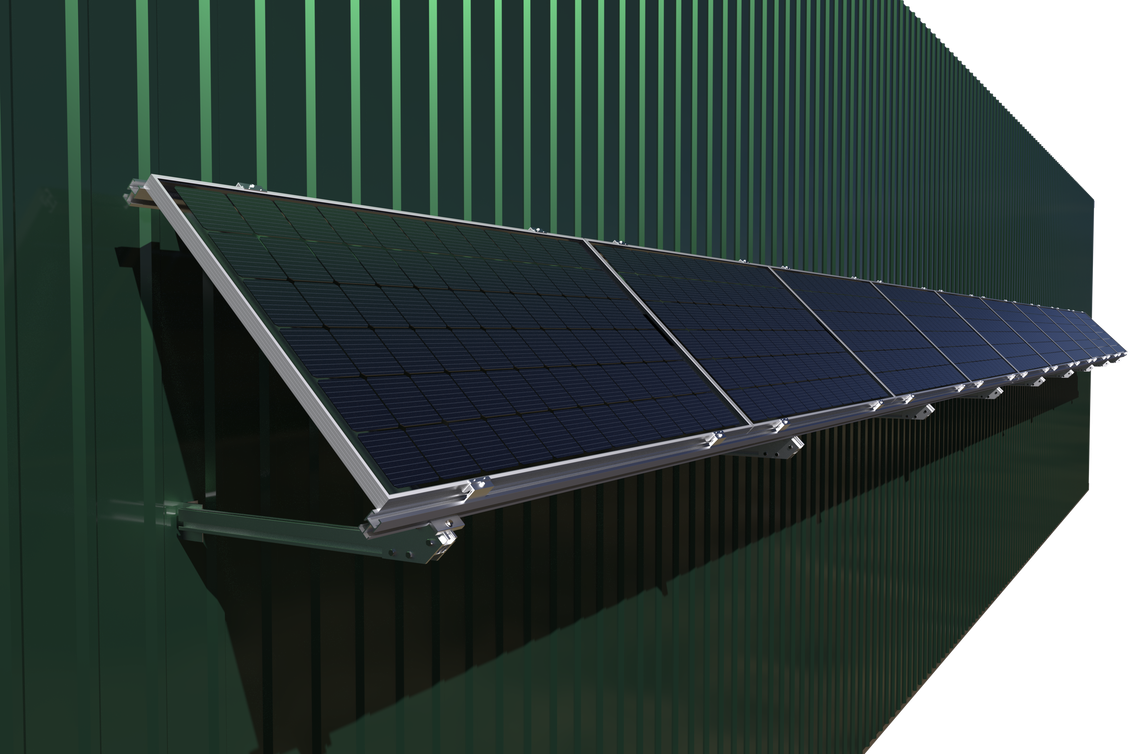

Freedom of design

Optimize for bifacial

Complete turn-key engineering services

Advantages

Fewer wall penetrations per PV

Better Panel Protection

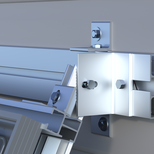

Full Aluminum Design

Fully Adjustable System On-Site

Highest Standard for Engineering & Support

Our engineers use only the safest methods of calculation, to assure maximum solidity and durability of the structures. We have proprietary, recent wind tunnel tests with Western University, and we design using the latest Building Codes (ASCE-7-16, NBCC 2016, IBC 2018), as well as SEAOC PV2 notions of array size versus roof size to account for extraordinary vortices. Minimal deflection allowed on rails, and finite element analysis done with high-end 3D engineering software. Each zone ballast & anchors calculated individually. We find solutions to each unique challenge, and we react quickly if unforeseen events happen during construction (such as unmarked drains, roof equipments obstruction and last minute changes).

Project-Specific Building Permit Plans & P.Eng stamp with each project

Custom, project-specific building permit plans, stamped by a local P. Eng., are provided for each job, describing step-by-step where each component goes, on the exact project site, with markups, details and explanations custom to each project's specific difficulties.

Documents & Specifications

OPSUN Total Engineeringtm Support

Flexible Design

Opsun's racking is not a single product : it is instead a large library of rails, components and configurations that we can adapt to match any client's requirements.

Full engineering Support

Opsun experts takes care of all the mechanical aspects of your solar PV project and we deliver detailed, project-specific set of engineering plans to help accelerate installation time.

Technical Solutions

Opsun is your solution finder to a wide array of challenges, such as limited roof capacity, directly attached or hybrid (both ballasted & anchored) systems.

Installation Support

Opsun On-Site Support allows your installation team to benefit from the instructions and supervision of an expert from Opsun's team, with 15 years of experience.